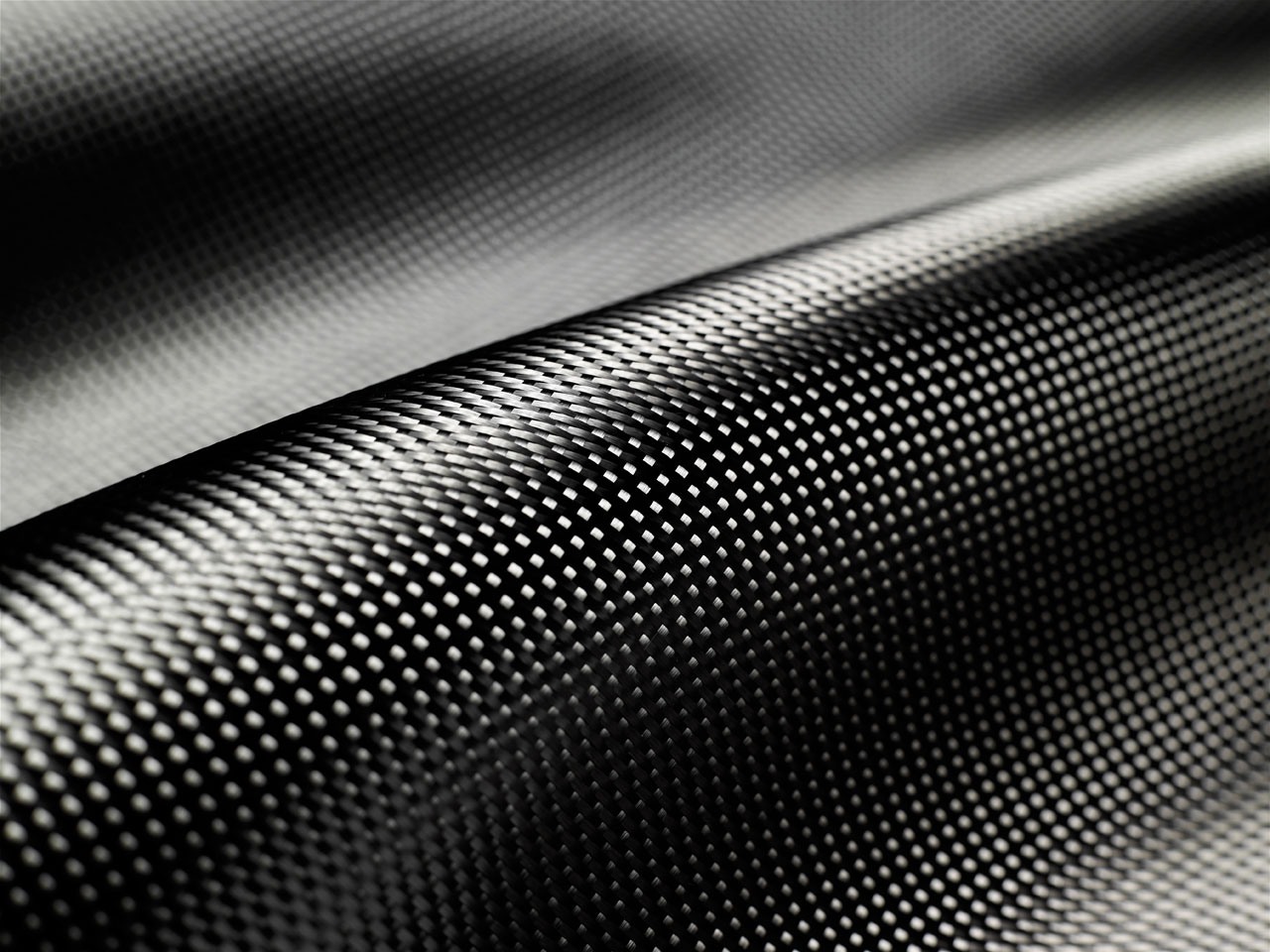

Engineers are feel affection for with carbon fiber stuff. The cause at the back this is its properties. It is five times the potency of steel and weighs two thirds less. It is probable for a carbon fiber to emerge in skinny strands. It is probable to produce carbon fiber strands thinner than a human fur. These strands can be woven into preferred form and dimension. It is simply after this process that the stuff takes an everlasting nature. Based upon the obligation of the industry or carbon fiber manufacturers, the requirement and the employs alter frequently.

Equally automatic and chemical measures caught up in generating carbon fiber. The foundation stuff is carbon. In order to bring out elongated strands of carbon, the stuff is intense to high warmth. The procedure does not use oxygen and is totally passed up. The heating process is performed in enclosed elements that eliminate all the oxygen from the air prior to making a static ambiance. As there is no attendance of oxygen, there is no procedure of burning. It is under this state that the substance experiences carbonization.There is still a extended manner to generate carbon fiber to the masses. Most of the heap construction activities have failed owing to augmented claim for expert personnel.

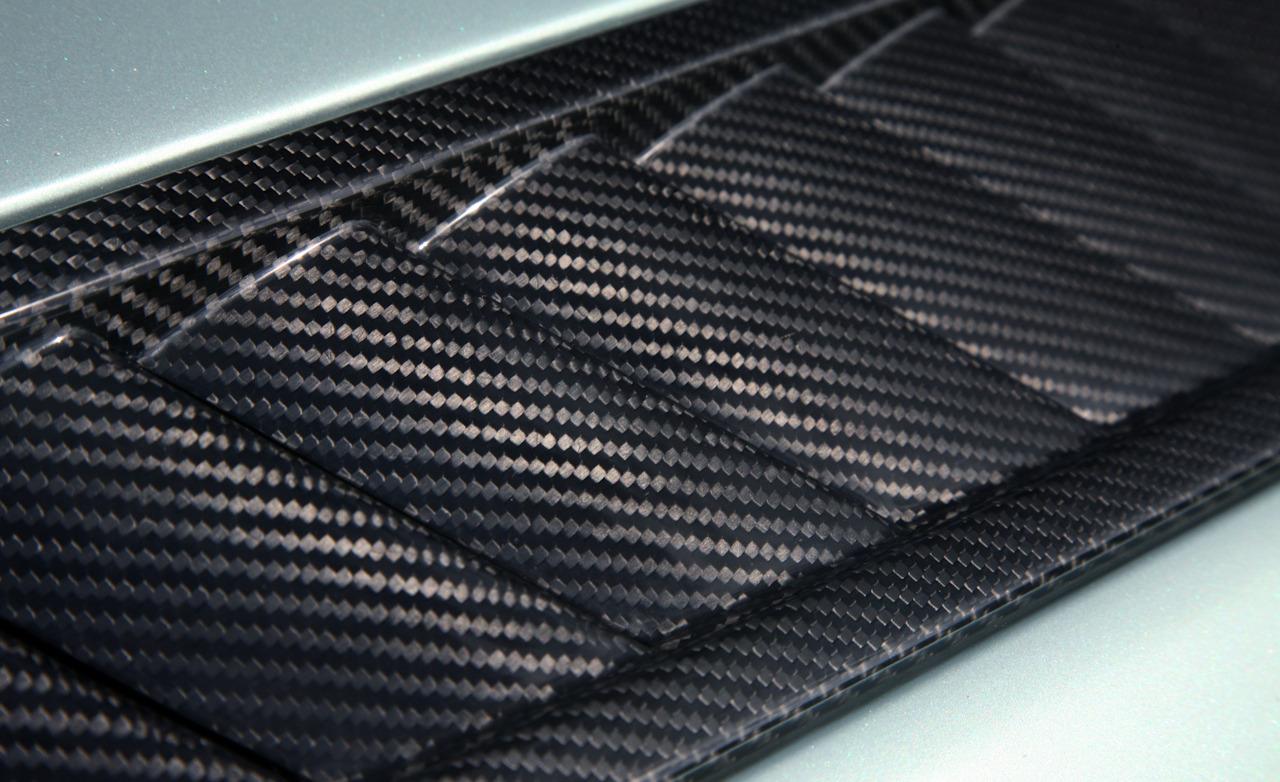

The process is costly and needs particular organization. It is essential to pursue numerous security features in order to keep away from health risks. It is essential for an employee to way defensive masks and consistent to stop breathe in carbon fiber elements. Owing to its amazing properties, the substance is widely employed in aerospace and motorsport industries. It is furthermore discovering its utilizing in common amusement products such as musical instruments for augmented constancy, consequence and condensed using up of power. Utilization of carbon fiber or carbon fiber products as a motor vehicle body will decrease the in general weight by over 60%. Such drop in weight augments competence and decrease fuel utilization.

In the carbon Fiber wet layup procedure, the hint is in the name. A shape is usually employed finished out of fiberglass or metal, for preeminent consequences out of carbon itself. An overturn form is prepared by wrapping the object to be prepared of carbon with wax and after that fiberglass matting and resin to figure the shape. Formerly dehydrated, the inside of the shape is waxed to figure a none-stick face. Yet again while dehydrated, the shape is enclosed with resin and left to dehydrate until cheap. Formerly cheap, the carbon fiber interlace cloth is laid onto the resin in the way you would like the weave. After that formerly in place, more resin is brushed into the carbon weave until a consistent width all through. The pattern is after that left to dry out prior to the carbon plug can be detached. This is perfect for stuff similar to carbon ornaments or car parts. This procedure though is extremely time consuming and the procedure of brushing in the resin can origin air bubbles in te resin formulating the artifact absorbent. Damp in the resin can cause an overcast affect and cannot be detached without sanding past it. You can get many elegant carbon fiber suppliers that offer Carbon Fiber product.

No comments:

Post a Comment